Franklin Electric 6″ encapsulated motors, manufactured in ISO 9001 certified facilities, are built for dependable operation in 6″ diameter or larger water wells. Water lubricated thrust and radial bearings enable a maintenance free operation. A special diaphragm ensures pressure compensation inside the motor. The motor is filled with a special FES91 fluid, providing frost protection down to -15 °C storage temperature.

The Sand fighter® SiC seal system is standard.

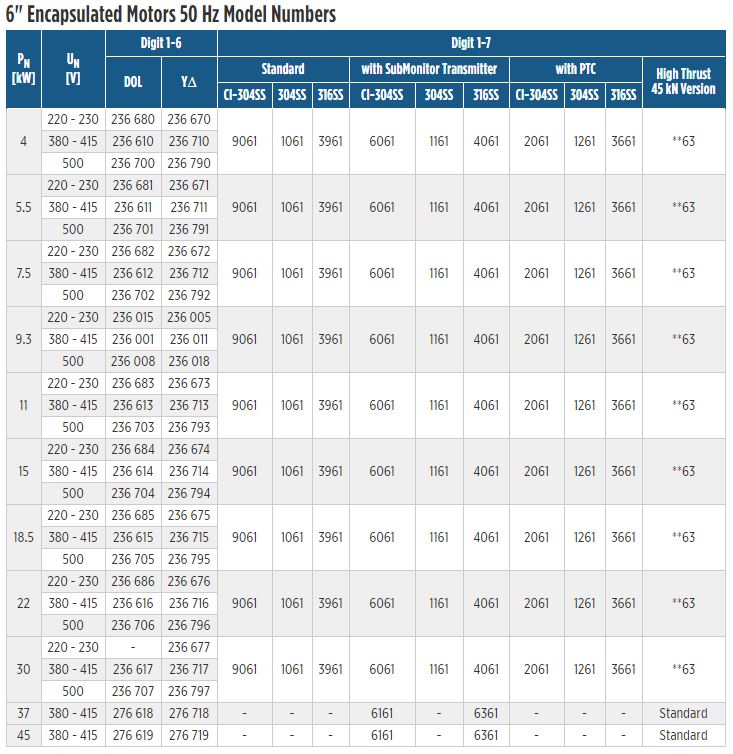

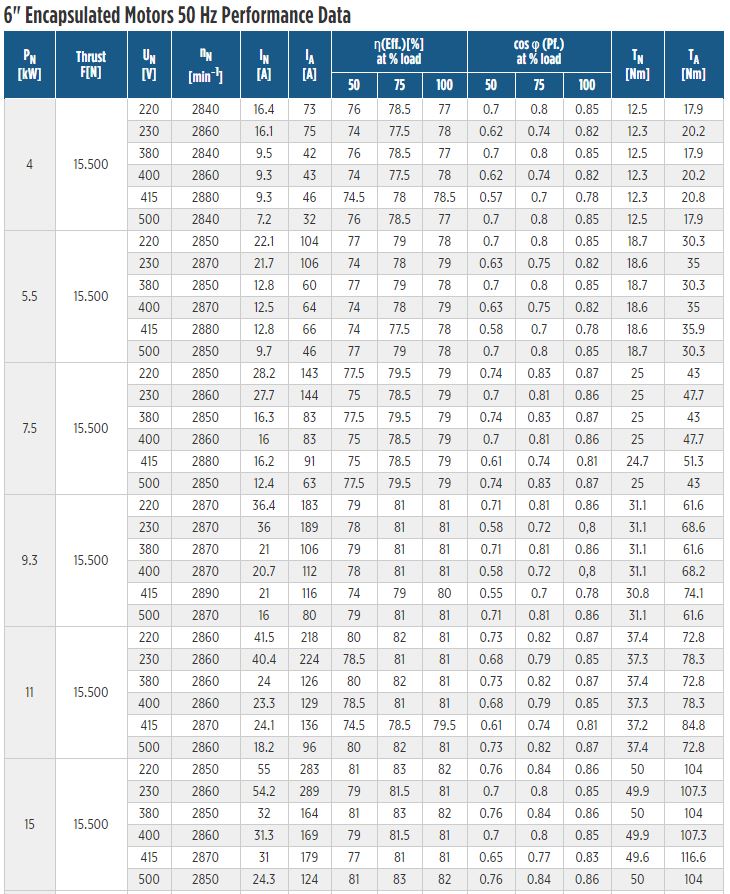

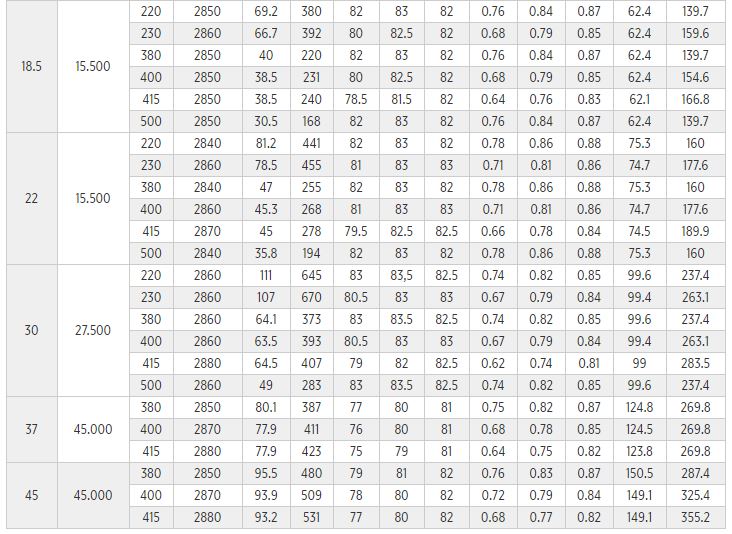

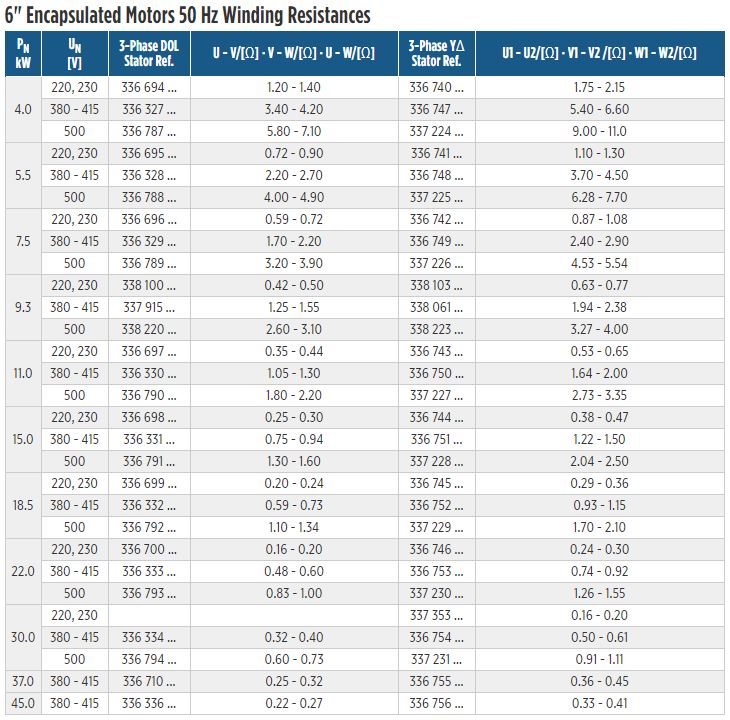

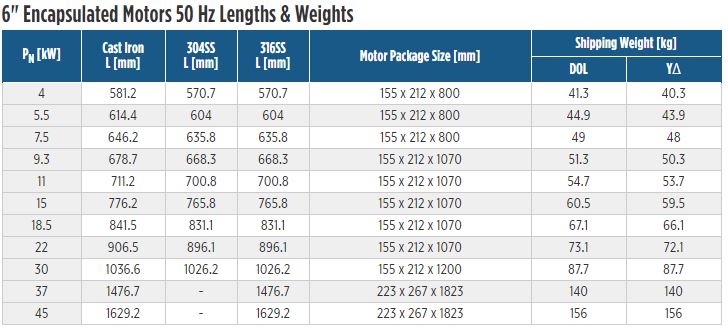

Specifications

- Hermetically sealed stator, anti track, self healing stator resin prevents motor burn out

- 37 and 45 kW Motors up to 50 °C ambient temperature

- Removable “Water Bloc” lead connector

- Cable material according to drinking water regulations (VDE / ACS / KTW approved)

- Sand fighter® Motor with SiC mechanical seal

- High efficiency electrical design for low operation cost

- All motors prefilled and 100 % tested

- Max. storage temperature -15 °C – + 60 °C

- Non contaminating FES91 -filled design

- 45kN thrust capacity (standard in 37 kW and 45 kW motors)

Technical Specification

- 4 – 45 kW

- 6″ NEMA flange

- Protection: IP 68

- Starts per hour: max. 20

- Installation: vertical/horizontal

- Standard Voltage: 380-415 V/50 Hz, 460 V/60 Hz

- Voltage tolerance 50 Hz from nominal: -10 %/+6 %

- Voltage tolerance 60 Hz: ±10 % UN

- Motor protection: Select thermal overloads according to DIN 61947-4-1

- Insulation: Class F

- Rated ambient temperature: 4- 30 kW up to 30 °C; 37 & 45 kW up to 50 °C

- Cooling flow: min. 0.16 m/s

- Motor lead in 4 m length (VDE / ACS / KTW approved)

Options

- Other voltages

- 45 kN High Thrust version (standard in 37 / 45 kW motors)

- Motors complete in 304SS and in complete 316 SS

- PT 100 temperature sensor (sold separately)

- Special Lead lengths up to 50 m

- Built-in SubMonitor Transmitter (standard for 37 & 45 kW)

- Built-in PTC temperature sensor