Franklin Electric 12″ rewindable motors, manufactured in ISO 9001 certified facilities, are built for dependable operation in 12″ diameter or larger water wells.

It is fitted with water lubricated radial and thrust bearings for maintenance-free operation. The motor is filled with a special FES93 fluid, providing frost protection down to -15 ºC storage temperature.

A special diaphragm ensures pressure compensation inside the motor.

The Sandfighter® SiC seal system is standard. For applications in aggressive media, motors made of 316SS are available.

Product Advantages

- Easy to assemble with 12″ double flange

- Cable material according to drinking water regulations (VDE / ACS / KTW approved)

- Sand fighter® SiC seal system for high performance in sand

- High efficiency electrical design for low operation cost

- All motors prefilled and 100 % tested

- Max. storage temperature -15 °C – + 60 °C

- Design for retrofitable PT100 sensor

- Non contaminating FES 93 filled design

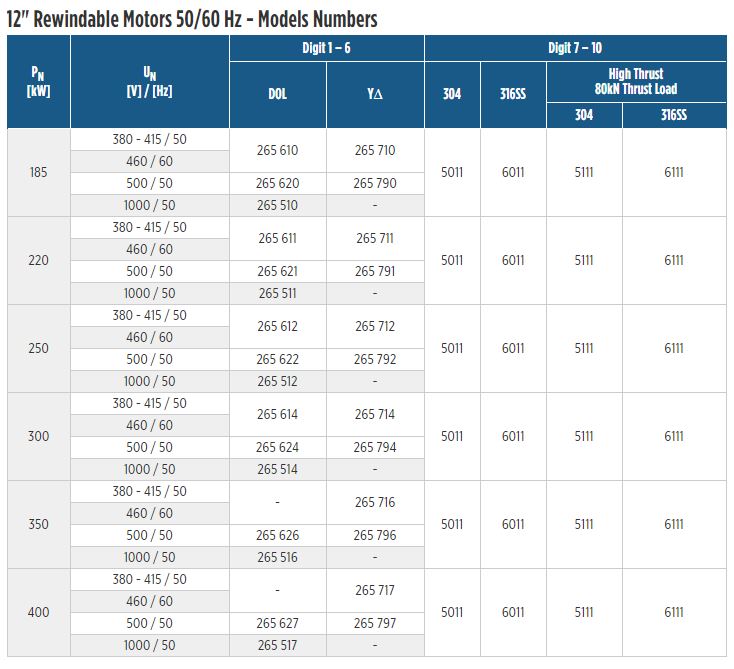

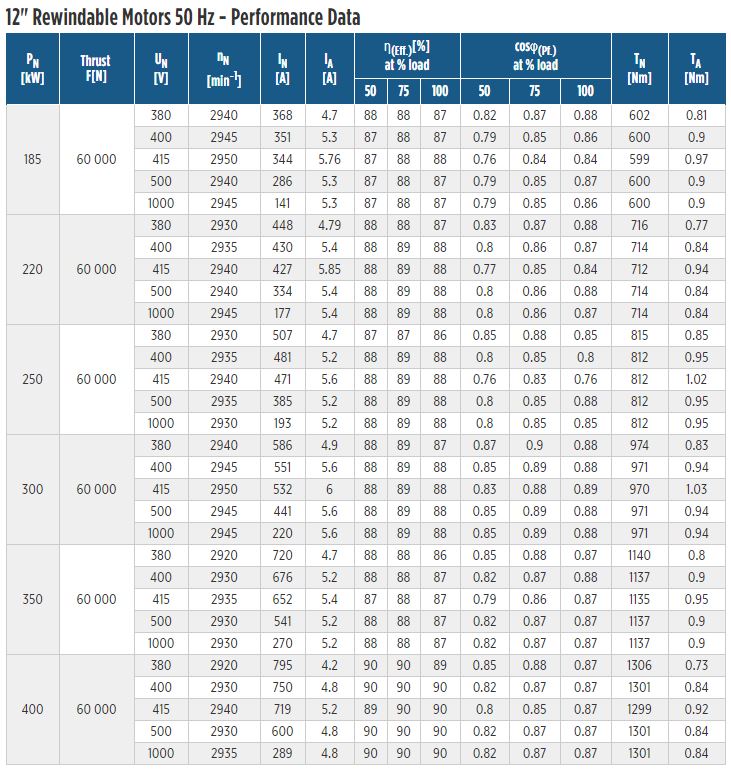

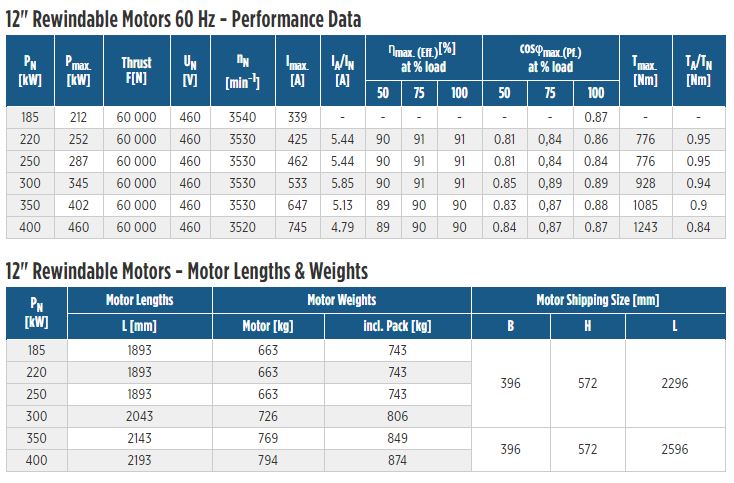

Technical Specifications:

- 185 – 400 kW

- 12″ double flange

- Protection: IP 68

- Starts per hour: max. 5

- Installation position: vertical / horizontal

- DOL – start / YΔ – start (pos. of cables 90 °C)

- Motor Lead in 6 m length (KTW approved)

- Standard voltage

- 380-415 V/50 Hz, 460 V/60 Hz

- 500 V/50 Hz

- 1000 V/50 Hz

- Voltage tolerance 50 Hz: -10 % / +6 % UN [380-415 V = (380-10 %) – (415+6 %)]

- Voltage tolerance 60 Hz: ±10 % UN

- Motor protection: Select thermal overloads according to EN 61947-4-1

- max. ambient temperature 30 ºC with a min. cooling flow:

- v = 0.5 m/s

Options:

- 80 kN thrust load

- Other voltages

- PT 100 temperature sensor (sold separately)

- Special lead lengths upon request