SubTronicSC® range covers all PSC motors from 0.25 kW to 2.2 kW for all voltages. Ergonomic design, attention to detail and unique features make the SubTronicSC® motor starter range your first choice when considering submersible motor protection. In conjunction with Franklin Electric submersible motors you now have a tangible water system advantage resulting in ease of installation and reliable protection.

Specifications:

- Attention to detail – every aspect engineered for the application

- The complete package – the device is 100 % compatible with the motor characteristics

- All in one name – reliability backed by the leader in submersible motors

Ergonomically designed

- Mounting: easy wall mounting offering various options without destroying the protection rating of the enclosure.

- Wiring: reliable connectors are provided for ease of wiring.

Motor compatible design

- Matching range: the SubTronicSC® protector range was designed to match the Franklin Electric range of PSC motors.

- Wide range of operation: compatibility with motor design allows for a wide range of operation resulting in minimized nuisance tripping.

Intelligent Protection and Management Features:

- Dry-run detection (without probes): prevents motor and pump damage due to running the pump without water based on a proprietary reliable detection method.

- Dry-run auto-reset: dry-run reset time is based on a proprietary search algorithm to find the best operating point for weak wells. Reset time 6 to 60 minutes.

- Over & under voltage: prevents motor damage that may be caused by abnormal voltage conditions without limiting the range of operation, made possible by matching the design of the SubTronicSC® Protector with the motor. Reset time approximately 3 minutes.

- Over current protection: prevents operation under conditions where motor current may exceed safe levels due to bound pump or other fault condition. Detection is based on current heating capacity measurement to prevent unnecessary nuisance tripping. Reset time approximately 10 minutes.

- Faulty start protection: prevents system damage due to factors such as faulty contacts or switch. Contact failure detection reacts fast and will prevent damage to system components

- Rapid cycle protection: prevents system damage due to factors such as continuous rapid cycling and excessive motor thermal cycling caused by waterlogged tank, faulty contacts or faulty pressure switch.

Indicators:

- Status: indication shows normal operation or other condition.

- Voltage: faulty voltage condition is indicated.

- Fault conditions: dry-run, over current, rapid cycling, and faulty start are indicated

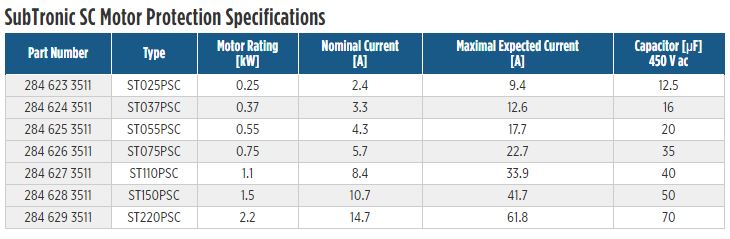

Technical Specification

- Mechanical

- Protection level: IP54

- External dimensions: 290 x 230 x 95 mm

- Weight: 0.6 – 1.0 kg

- Mounting: Wall mounting (with options)

- Temperature: -5 °C – +40 °C

- Humidity: 50 % at 55 °C (without condensation)

- Electrical

- Voltage: 220 – 240 V; ± 10 %; 50 Hz 1-phase

- Current: 16 A

- Power: 0.25 – 2.2 kW

- Standards

- IEC 60439-1 when supplied with suitably fused supply