Franklin Electric 4″ encapsulated submersible motors, built in ISO 9001 certified facilities for outstanding performance in 4″ or larger water wells.

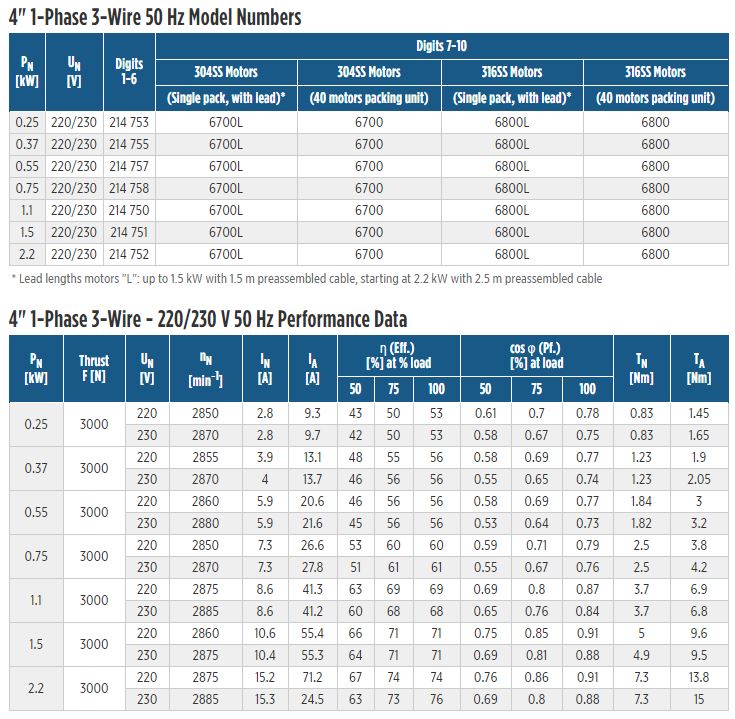

The 1-phase 3-wire motor has been designed for highest achievable starting torque and shaft power from 1-phase power supplies. It is therefore ideally suited for applications where starting torque is paramount and 3-phase motors cannot be used. It should ideally be combined to the Franklin Electric 3-wire control boxes for maximum system performance, protection and warranty.

Standard Motor Design Specifications

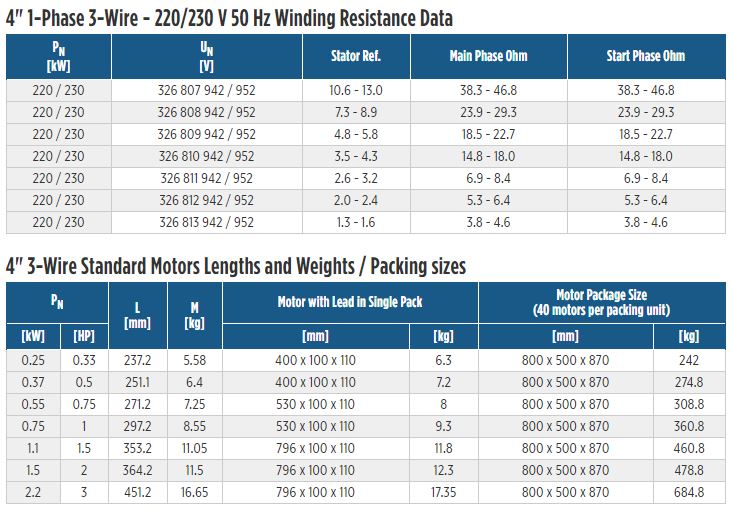

- Hermetically sealed stator. Anti track, self healing stator resin prevents motor burn out, mechanically supports the winding and provides fast heat dissipation.

- High efficiency electrical design (low operation cost, cool running winding)

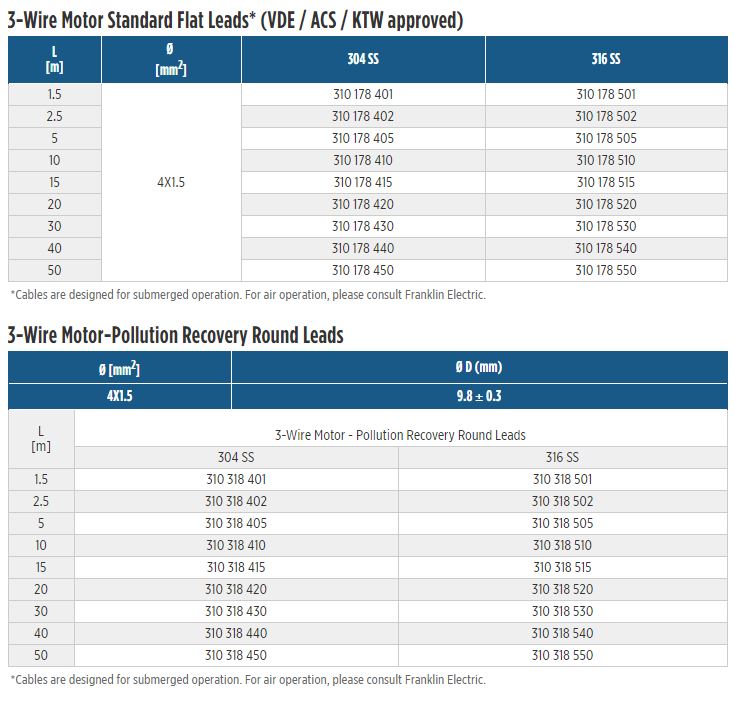

- Cable material according to drinking water regulations (VDE / ACS / KTW approved)

- Removable water bloc lead connector

- No-wear, water lubricated radial and thrust bearings for 100 % maintenance free operation.

- Non-contaminating FES 93 filling liquid

- Various agency approvals for use in drinking water

Pollution Recovery Motor Version Specifications:

- Fluorelastomere (Viton®) rubber parts

- Special Polyuretane (PUR) lead assemblies

- 304 graded stainless steel as standard, 316SS as an option

Technical Specification

- 3-wire motor range: 0.25 – 3.7 kW

- 4″ NEMA flange

- Rotation: CCW facing shaft end (CW upon request)

- Degree of protection: IP68

- Insulation: Cl.B

- Rated ambient temperature: 30 °C

- Required cooling flow: min. 0.08 m/s

- Max. starts/hr.: 20, equally distributed

- Mounting: vertical to horizontal, shaft upwards

- Voltage tolerance 50 Hz from nominal: -10 % / +6 %

- Voltage tolerance 60 Hz from nominal: ±10 %

- Protection requirements: EN 60947-4-1

Options

- Motor cable VDE / ACS / KTW approved (1.5 m; special lengths available)

- Motors with factory-installed lead in single packing

- Alternative material executions

- Built-in lightning arrestor

- Built-in overload protection